Lesson 3 - Advanced materials for thermal protection

ADVANCED MATERIALS FOR THERMAL PROTECTION

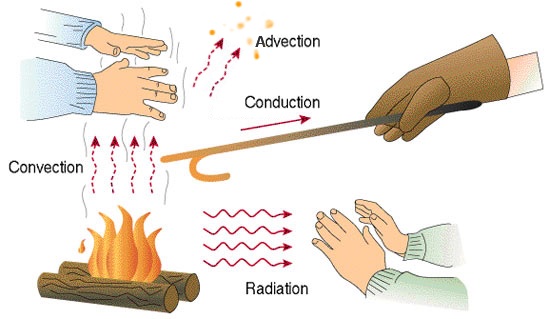

Textiles for thermal protection may be used against exposure to extreme high or low temperatures, for mitigation of health hazards by longterm exposure to temperatures outside the human thermos‐physiological temperature limits or for avoiding discomfort, usually under intense physical activity. The main mechanisms for thermal protection textiles are thermal insulation and regulation of heat transfer. Advanced and smart materials may incorporate temperature sensors as well as 3D structures and properties changing textiles responding to different conditions. Extreme temperature protecting wearables are mostly based on insulating properties, aiming to maintain body heat, produced by metabolic activity, from escaping to the environment or avoiding environmental heat from reaching the body.

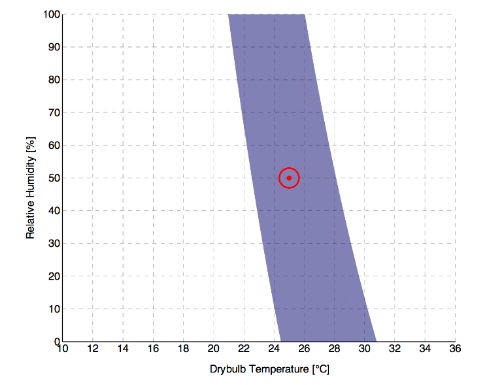

The human body generates heat through metabolic activity and needs to maintain a quasiconstant temperature of 36.6±5 °C. Depending on the ambient conditions, humans need to retain or discharge body heat. The comfort zone for humans lies at temperatures between 22 °C to 27 °C and relative humidity (RH) between 40% and 60% [1]. Evolution has deprived the human body of the fool body fur, which acts as a heat transfer regulator for most mammals. This function is more or less substituted by the use of garments for entrapping body heat and sweating for discharging excess heat.

Heat transfer mechanisms. Kmecfiunit, cmglee, CC BY-SA 4.0, via Wikimedia Commons

References

1. ASHRAE Standard 55-2004. “Thermal environmental conditions for human occupancy”. American Society of Heating, Refrigerating and Air-Conditioning Engineers Inc., Atlanta, 2004.

2. Khadse N, et al. Temperature Responsive PBT Bicomponent Fibers for Dynamic Thermal Insulation. Polymers (MDPI). 2022, 14, 2757.

3. Chen Y, et al. Laminated PET-based membranes with sweat transportation and dual thermal insulation properties. Chemical Engineering Journal. 2022, 450, 138177.

4. Xu Y. et al. Gradient assembly of alginic acid/quaternary chitosan into biomimetic hidden nanoporous textiles for thermal management. Carbonhydrate Polymers. 2023, 300, 120236.

5. Wang L, et al. Large-scalable polar bear hair-like cellular hollow fibers with excellent thermal insulation and ductility. J Appl Polym Sci. 2022, 139, e53018

6. Gonzalez G. M, et al. para-Aramid Fiber Sheets for Simultaneous Mechanical and Thermal Protection in Extreme Environments. Matter 3, 742–758, September 2, 2020

7. Li M, et al. Ultralight aerogel textiles based on aramid nanofibers composites with excellent thermal insulation and electromagnetic shielding properties. Composites Communications 35 (2022) 101346

8. Zou S, et al. Facile and scalable fabrication of stretchable flame-resistant yarn for temperature monitoring and strain sensing. Chemical Engineering Journal 450 (2022) 13846

9. Wang L, et al. Developing smart fabric systems with shape memory layer for improved thermal protection and thermal comfort. Materials & Design 221 (2022) 110922